Click here to listen to the Audio verison of this story!

The boom/bust cycle has challenged the oil industry in many ways over the decades. Since the turn of the millennium, the newest challenge has been how to adopt new technology when there’s the frantic activity of a boom one minute and the layoffs and budget slashing of a bust a year or two later. How can new systems and procedures be adopted and trained in that scenario? That issue has put oil and gas far behind many other industries on the adoption of technology—and now artificial intelligence (AI) is added to the mix.

Kevin Gregory

Here, experts with Deloitte and Cognite will show how artificial intelligence works with IRL (in real life) intelligence to speed up the finding of solutions and to help every human to work at super speed.

One issue, said Kevin Gregory, AI leader for Energy and Chemicals, Deloitte, is that the industry did adopt some technology early on, at least regarding the simple remote monitoring of assets. “So, it’s always been that we were using it [technology] to control remote operating centers and things like that, to turn on red lights when something went down.” Technology did save some daily well site trips by pumpers, but operators still didn’t know of problems until after they happened. Collecting data on tank levels, motor temperatures, and run rates to proactively schedule offloading or to predict failures was not on the radar.

The second issue involves the challenges of planning and preparation for upgrading technology of any sort, especially something as advanced as AI. Said Gregory: “Technologies require more than just technology. They require the transformation of a process, probably implementation of additional resources with varied skill sets and things like that, that are more than a 12-month or 24-month commitment. If you want to be successful.”

In recent years the math side of remote monitoring has improved, he noted. It is now moving toward more predictive learning such as the monitoring of operating temperatures and other data for out-of-range readings in order to predict, and therefore prevent, a crash. The problem has been the ability to trust the sensors, whether that monitored data is equal to having physical and eyes and ears on site.

If the remote system even just might miss a breakdown, the thinking for hesitant producers becomes, “If are you saving 10 percent of your workforce, but you’re risking 25 percent of your revenue, let’s not [depend on the sensors].”

First came remote monitoring of oilfield installations. Then came the broader digitization of the oilfield. Now the power of supercomputers is taking the oilfield, via AI, to greater technological refinement. The AI conversion of the O&G industry is truly a broad-based phenomenon, as this graphic from Kent shows.

AI Ups the Game

The next step is to let Generative AI “play traffic cop across other AI technologies and other kinds of technologies,” he suggested. The industry is advancing already in using AI for “sending drones up to monitor things using cameras, to pay attention to an asset or a location.” But the key lies in combining AI with the data science that tells operators what the visuals mean.

“Putting those two together is really where you can get value, and GenAI is really good at doing that,” Gregory said. When sensors alert humans to an anomaly in the field, a drone or a fixed onsite camera can give a visual to any other signs of a problem. Then GenAI can evaluate that and, if needed, send someone to the site for repairs or adjustments.

Embrace the Change

Another AI benefit lies in its ability to document changes in equipment operations over time. One industry question revolves around whether equipment is running “as designed and built, or as operated?”

Gregory continued, “The other side that GenAI is really good at doing is looking across what’s happened in the past on that asset and what has been different, then seeing what kind of procedures have been done that have been successful.”

This is where GenAI is “Getting the brain of the 35-year person into the head of the 35-day person in a very constructive manner.” Whereas the long timer could walk up to a location and immediately hear a worn bearing or note a slower motor speed, the new person can’t—but today they can tap into technology to bridge the knowledge gap.

With full reporting, GenAI can notice when a wellsite repair trip that usually takes an hour instead took 2-1/2 hours last time. The system can analyze what was done differently and make suggestions that can prevent mistakes and make personnel more efficient. It can also help even the 35-year person run through a checklist to prevent a memory lapse that could prove costly.

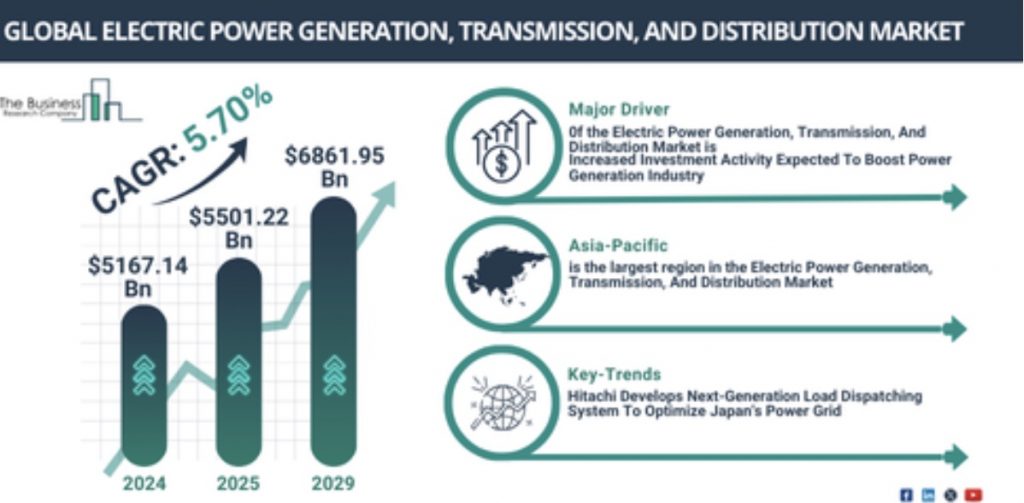

The Business Research Company, creator of the graphic shown here, has this to say: “The AI in oil and gas market size has grown rapidly in recent years. It will grow from $3.59 billion in 2024 to $4.06 billion in 2025 at a compound annual growth rate (CAGR) of 13.1%. The growth in the historic period can be attributed to data explosion in the industry, operational efficiency improvement, automation of repetitive tasks, safety enhancement, optimization of exploration and drilling processes, enhanced reservoir management.”

Adapting AI Requires Humans

As smart as AI can be, implementing it requires intention, planning, and training, Gregory said. The personnel of today and tomorrow will need to include AI-interfacing skills along with handling a wrench or a forklift in order to do their job. Gregory observed that larger operators may do more of this in-house, while small to mid-size firms farm out the design and implementation—but even smaller firms must at least a few people who lead the way in working with the system and training others.

The goal is always to make humans more productive. “You’ll end up with the concept of 10X engineers or 10X accountants,” meaning that they are ten times more effective at their jobs. “It’s because they can focus on the problems and overcoming the complexities, not on the 80 percent of their day job that is just doing the blocking and tackling that are required. We’re going to get the computers to do that,” he explained. “Just give me the data I need” to solve the problem.

Getting from Point A to Point AI

Everyone knows that AI handles billions of data bits in seconds, spitting out useful information that would take humans hours or days to assimilate and analyze.

Great!

But does AI automatically recognize your data and immediately know how to do all that?

As with most things, it’s not that simple—but laying the groundwork to get there pays huge dividends, said Kevin Scher, field CTO at Cognite. Cognite is an AI company that delivers industrial software to improve the efficiencies of industries such as energy and others.

The diversity of the data involved is one challenge, he said. He listed location through P&IDs (piping and instrumentation diagram, a sort of CAD representation of the entire well site), well planning documents, ERP (enterprise resource planning), along with “equipment spec and data sheets, which are typically PDFs.” Then there are “just gobs of time series data,” involving ongoing equipment readings from the field, which is “pretty simple, it’s just a time stamp and a value, but there are trillions of rows of this.”

All that diversity siloes the data because it’s in so many different formats. How is any system, AI or otherwise, to sort and manage this?

Scher pointed out that an engineer troubleshooting a wellsite issue with, say, a pump, needs AI to show them the whole interconnected picture. “What’s upstream of this pump? What’s downstream of this pump?” A failure in one piece of equipment affects everything on either side of it.

Context Is Key

Context Is Key

Putting all those rows of data into context for AI’s large language model is the key, Scher said. Those models like ChatGPT are trained on language and grammar, but industry-specific data must be contextualized separately.

The goal is for the engineer to ask the system, “I know that this asset reference in the asset hierarchy or in the functional locator documentation is referencing this tag from the time series data which is called out on this P&ID and which is referenced in this work order.”

Making those connections gives the AI a “knowledge graph.” With that, “I have a semantic or meaningful connection between all of those different data points that I can then navigate.”

In its need for context, AI is no different from people. For example, asking a person, “Is it all better now?” will invoke another question: “Is what all better now? What’s the context?”

What Does It All Mean?

Although AI won’t give an exact answer to an out-of-specs reading—at least not yet—it will make the engineer more efficient by narrowing down the likely causes, Scher noted. “I can ask AI based on this information what it thinks is the likely cause of the vibration and it can say, well, these are the top five things you should check. So, it can take something that might have taken hours or days to investigate, to prepare for down to minutes.”

AI’s help can extend beyond the field. In the office, it can look up all contracts with expiration dates within a month, or those with or without certain clauses.

Too Early—And Too Late?

In adopting new technology, timing can be everything. Anyone with a TRS-80 computer stuffed in a closet knows that it was too early to be of much use. But with AI, Scher noted, there’s some of both in the mix.

In trying to reassure reticent adopters, “You feel like you’re too early because the technology is still pretty nascent and it’s evolving. So, it feels like you’re delving into a space that’s not very stable yet in terms of what it’s capable of doing. And yet you feel like you’re late because it’s moving so quickly.”

But: “If you sit around and wait for it to become stable, you start falling way behind what’s possible.” In what sounds at first like a strange statement, Scher says he also tells people, “What you can do now is mind blowing—and this is the worst it’s ever going to be.”

So, what is next? Said Scher, “As time goes on, you’ll start integrating in other types of AI like machine learning with the generative AI that allows you to talk to it, and you’ll start getting into more autonomous control of equipment. It’ll be gated by safety and redundancy, but it’ll happen.”

Practical Applications

Cognite has partnered with oilfield service company SLB to use the data to power digital solutions in production operations. “Our partnership with SLB is interesting because they’re taking our data layer and they’re building solutions on top of it.”

Called OptiSite and OptiFlow

and OptiFlow , the applications use Cognite data to provide “insights, analysis and optimization solutions on top of that for the entire production operations—from pore to process.”

, the applications use Cognite data to provide “insights, analysis and optimization solutions on top of that for the entire production operations—from pore to process.”

One goal of many drillers is to standardize drilling operations to boost efficiency by replicating the operation at every well—a dream that Schern says is only that, a dream, and is the basis for instead using AI to recognize and adjust for the uniqueness of each well.

“You will never get all of those well sites to be the same. They won’t have the same equipment, [or] they won’t have the same even databases or data source.”

He continued, “So we take all of that data, even though it’s different and then we build what we call a data model, a standard view. And we publish that data into that standard view and then we build our applications based on that standard view. So, from the from the perspective of off the site or off the flow from SLB, all well sites look the same.”

That happens because “We sit underneath them, and we take all that stuff that looks different, and we publish it into a common view. So, by the time it gets to SLB solutions it all looks the same,” in order to simplify the uniqueness of each well.

By Paul Wiseman

The post What’s So Smart About Artificial Intelligence? appeared first on Permian Basin Oil and Gas Magazine.

pboilandgasmagazine.com (Article Sourced Website)

#Whats #Smart #Artificial #Intelligence