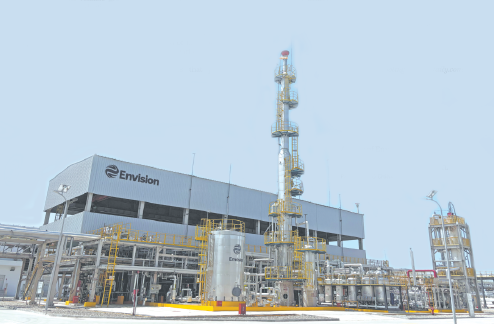

A view of Envision Group’s plant in Chifeng, Inner Mongolia autonomous region. CHINA DAILY

A view of Envision Group’s plant in Chifeng, Inner Mongolia autonomous region. CHINA DAILYThe application of green hydrogen-ammonia is facilitating transformation of the renewable energy sector, advancing carbon reduction goals and strengthening global green supply chains, while policy backing remains essential to accelerate its commercialization, industry insiders said.

The first phase (320,000 metric tons capacity) of Envision Group’s 1.52 million tons hydrogen-ammonia project, the largest facility of its kind in the world, in Chifeng, Inner Mongolia autonomous region, was commissioned in July.

As a vital chemical feedstock, ammonia offers dual advantages of high energy density and zero-carbon combustion, producing only water and nitrogen when fully burned. These properties establish it as a promising clean fuel for many sectors’ decarbonization transition.

A green hydrogen and ammonia project refers to an integrated model that combines wind-solar power generation, hydrogen production through water electrolysis and green ammonia synthesis, converting renewable electricity into hydrogen and hydrogen-based compounds for storage and transportation.

Green ammonia is extensively utilized in maritime fuel, industrial feedstock and fertilizer production with zero carbon emissions, providing an effective solution to renewable power consumption challenges.

Envision Group is a global leader in green technology, with operations spanning China, Germany, France, Australia, the United States, Japan and other countries and regions. It has established over 20 global operational headquarters and research and development centers, and owns more than 60 manufacturing facilities worldwide, the company said.

“Envision’s Chifeng net zero industrial park for green hydrogen and ammonia has pioneered a dynamic green production plant, achieving integrated dynamic synthesis of hydrogen and ammonia from renewable power,” said Zhang Jian, chief hydrogen engineer at Envision.

Zhang said that on the power generation side, the new power system provides reliable green electricity for production. On the production side, the fully dynamic green plant seamlessly synchronizes with variable upstream renewable power supply resources. This ensures every kilowatt-hour of green electricity can be maximally utilized, achieving holistic system stability.

Modular hydrogen-ammonia plants are easily replicable globally, accelerating green hydrogen and derivatives commercialization while supporting decarbonization in shipping, aviation, steel and chemical sectors, Zhang added.

The project’s commissioning achieves seamless integration of wind-solar storage systems with green hydrogen-ammonia production, providing robust support for local new energy industrial chain development and industrial upgrading, said Luan Tianmeng, mayor of Chifeng.

“Envision’s Chifeng industrial base will harness perpetual wind and solar energy, transforming it into green fuels to power global development. It will provide continuous energy for new green industries, while China’s renewable technologies advance from Chifeng worldwide, driving global prosperity,” said Zhang Lei, CEO of Envision Group.

Jinzhou, Liaoning province, a coastal city with a port enabling global distribution of green hydrogen-ammonia products, and Chifeng, a wind-solar power generation base, are driving regional collaboration through complementary supply chain synergy, said Li Jinbing, deputy mayor of Jinzhou.

“A major challenge facing the green hydrogen-ammonia-alcohol industry is its current inability to achieve direct commercialization due to high costs,” said Wang Weidong, director of the Chifeng energy bureau.

Envision is pioneering full-scenario, full-process cost-reductions through experimental demonstrations, which play a demonstration role in advancing China’s green hydrogen-ammonia sector toward commercialization, Wang said.

The deployment of green hydrogen-ammonia-alcohol products provides an innovative model for advancing China’s zero-carbon industrial parks initiative and new power system. It pioneers commercial models for green hydrogen and ammonia industries while enabling holistic development across production, storage and utilization chains, establishing a benchmark for green energy transition, Wang added.

“We have secured strong market adoption in decarbonizing shipping, power generation, chemical and steel sectors, with growing confidence to expand green ammonia sales,” said Yu Feng, head of Envision’s hydrogen energy market product line.

The project’s implementation demonstrates that producing green ammonia from renewable power is economically viable and commercially feasible, Yu said.

A landmark example of ammonia’s application as a clean fuel is the world’s first pure ammonia-powered demonstration vessel Anhui, which successfully completed its maiden voyage in Hefei, Anhui province, in June — a major breakthrough for green shipping.

The ammonia-powered Anhui was jointly developed by the Institute of Energy of the Hefei Comprehensive National Science Center and its subsidiary, Shenzhen Haixu New Energy Co Ltd.

The maiden voyage achieved stable combustion of pure ammonia fuel, nearly zero carbon dioxide emissions and effective control of nitrogen oxides, said Wu Dianwu, deputy director of the hydrogen energy and ammonia application research center at the institute.

It confirms the potential for ammonia-hydrogen fuels to be widely used in marine and land transport, as well as in industrial boilers and fuel cells, Wu said.

Wang Junli, secretary-general of the Chinese Society of Naval Architects and Marine Engineers, said the vessel’s successful voyage represents a significant breakthrough in developing clean fuel systems for shipping.

If pure ammonia engines reach the megawatt level, their applications will expand significantly, holding significant importance in achieving China’s dual carbon goals, Wang said.

“Moving forward, our research institute and corporate technical teams will adhere to market-oriented and industrialized approaches to intensify R&D for technological breakthroughs, optimize engineering solutions, upgrade equipment and continuously enhance the safety, stability, reliability and cost-effectiveness of ammonia-fueled vessels,” Wu said in an interview with Science and Technology Daily.

It is equally crucial to aggressively develop standardized, modular products to reinforce foundations for scaled application and industrial deployment of ammonia fuel, Wu added.

“Hydrogen energy will assume growing significance in achieving carbon reduction targets. However, ensuring project sustainability remains a critical challenge,” said Lin Boqiang, head of the China Institute for Studies in Energy Policy at Xiamen University.

Following technological advancements, cost-effectiveness emerges as the primary challenge, given that resolving technical issues fundamentally aims to enhance efficiency and reduce costs, said Lin.

As the subsequent commercialization process becomes of great importance, Lin suggested that appropriate fiscal support from the government is required to help reduce costs.

Green ammonia boasts broad application prospects given its dual role as both industrial feedstock and fuel, offering operational flexibility, said Yang Lei, deputy dean of the Institute of Energy at Peking University.

Through continued R&D advances, its utilization will further expand, playing a pivotal role in advancing industry integration and supply chain maturation, Yang said, adding that enterprises need to accelerate development of downstream application scenarios across the industrial chain, as China’s green ammonia industry remains in a nascent stage.

Proactive expansion into overseas markets will help explore applications for domestically produced green ammonia, facilitate accelerated formation and development of industrial chains, and create new engines for economic growth, Yang said, adding that from the governmental perspective, beyond supportive policies and financial subsidies, reforming institutional mechanisms remains indispensable — such as developing market ecosystems and establishing talent recruitment frameworks.

![]()

![]()

www.ecns.cn (Article Sourced Website)

#Hydrogenammonia #role #CO2 #goals #rising