Click here to listen to the Audio verison of this story!

Optimizing chemical treatments requires knowledge of the formations, according to BASF’s George Herman, flanked here by two BASF team members.

Enhanced oil recovery (EOR) in conventional fields has been a long-accepted method for extending productive life. Not so much for unconventional tight shales, because water floods and CO2 floods don’t communicate or flow through those tight formations. But advanced EOR technologies are showing promise for both conventional and unconventional wells which, along with the lack of good new prospects, are enticing producers to open up to the new possibilities

For example: BASF provides carefully crafted EOR chemicals, ESalinity has seen improvement in conventionals by using same-formation water for floods, and Shale Ingenuity is breaking through unconventionals’ resistance to EOR at all, with great results.

Rethinking Tight Shale EOR

Other than refracturing, there has been little success in enhancing oil production from shale wells, which notoriously cling to more than 90 percent of their hydrocarbon content. But Shale Ingenuity Founder and CEO Robert Downy says his company has a new and proven procedure that releases up to 500 percent more oil. (In other words, up to five times more oil than a well would obtain without it.)

There are two variations of Shale Ingenuity’s system—SuperEOR and UltraEOR—which, Downy says, “were born out of the recognition that most shale oil wells are producing from a shale rock matrix that has extremely low porosity.” Further, he says, “the formation oil is undersaturated with natural gas; hence, there is limited energy available to drive the matrix oil and gas very far through the pores into fractures and up the wellbore.”

Their two systems use proprietary liquid hydrocarbon solutions that “provide high concentration solution drive energy, reduce oil viscosity, reduce interfacial tension and capillary pressure, and increase advection and diffusion.”

Downy says these solutions outperform natural gas and CO2 injection and, depending upon a formation’s characteristics, “SuperEOR can increase EUR (estimated ultimate oil recovery) by 100 percent to 500 percent.”

UltraEOR adds to SuperEOR’s formulation in the fracturing process, using the proven formulation to “significantly increase the number of fractures along the lateral to enable the injected liquid hydrocarbon solvent solution to extract more oil from the shale rock matrix,” said Downy.

During production, the solvents are recovered and reused repeatedly, which helps keep treatment costs down. The system used for these solvents takes about 6-12 months to design and install, he explained, and they can treat anywhere from two to 20 wells. They are designed to run for 10-20 years.

Once installed, “Injection and flowback cycle times will vary depending on the lateral lengths of the project wells and the number of frac stages in the wells but are generally 5-20 days of injection and 20-50 days of flowback per cycle,” he added.

Downy said the initial production rates from the EOR processes may exceed the well’s first production after initial completion, and they often decline much more slowly.

Shale Ingenuity is breaking through unconventionals’ resistance to EOR.

Industry Acceptance on the Rise

Because older restimulation method results were less than stellar, Downy said producers are often reluctant to try any new EOR method. But as SuperEOR and UltraEOR field results show excellent results, that’s starting to change, with more operators responding to Shale Ingenuity’s story.

He added that shale EOR requires “substantially different technical and operational skillsets and a different approach to asset and reservoir management. But we believe that continued success in the field will cause more companies to consider it.”

Esal is finding that a field’s productivity can at times be significantly enhanced simply by switching the completion fluid from fresh water to produced water from the same formation. The company has also boosted oil production by adjusting the salinity of injected water to match a formation’s wettability.

Using Same-Formation Produced Water for EOR

What if a field’s production could be significantly enhanced simply by switching the completion fluid from fresh water to produced water from the same formation? A recent field study by ESal’s Chief Technology Officer Geoffrey Thyne shows that, in many cases, that alone can increase production by up to 500 percent.

For years now ESal (Engineered Salinity) has made its living boosting oil production by adjusting the salinity of injected water to match a formation’s wettability. And that is still its most popular service.

And then, a 2022 Thyne discussion with a client targeting the Yeso Formation in New Mexico brought some better-than-expected results just by switching water sources. Apart from the question of what chemicals might be used, he suggested to the producer, “Produced water would be better for the wettability of the formation, and you should see a couple things if you do it.”

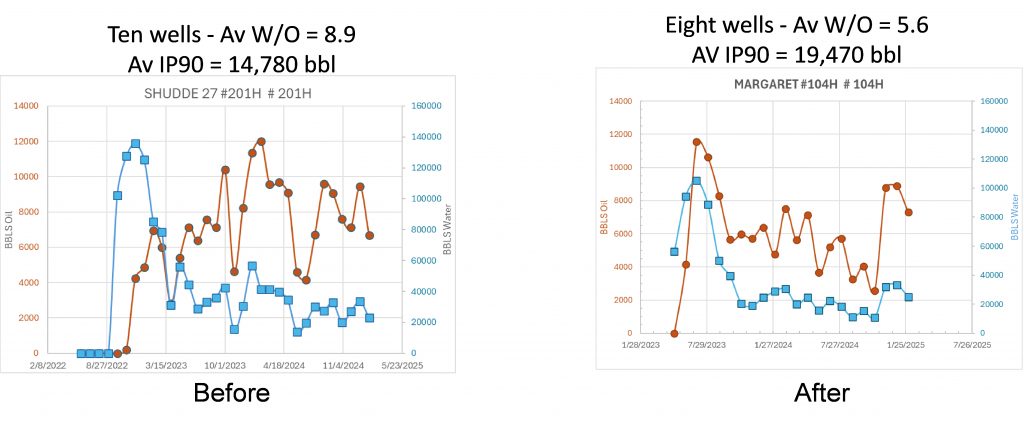

Producing more oil would, of course, be the most significant of the two, and producing less water would be a strong second. In this case, the operator had drilled 10 wells in 2022 using fresh water. Changing to produced water was encouraged both by Thyne’s idea and simultaneously by increased pressure from the State of New Mexico to cut freshwater use.

So, in 2023 they drilled eight wells under Thyne’s suggested method of using produced water from the pit that held nearby wells’ produced water. Because the water came from the onsite pit, Thyne noted that there was not a way to add the extra step of optimizing for salinity.

The difference was clear immediately, once the results were optimized to account for varying lateral lengths among the wells. “The use of produced water increased oil recovery about 20 percent and cut water production about 40 percent.” This was based on 2024 data. That covers about two years for the test group.

In addition, “The water-to-oil ratio improved 27 percent. The IP90 (initial oil production over 90 days) went up 20 percent. And the IP180 was up 31 percent.” Those percentages came from comparing ten freshwater completions to the eight produced water wells, all in the Yeso formation.

Yeso Conventional—or Yes or No?

While the Yeso is considered a conventional formation, Thyne said he was told by a geologist with the company that it has at least a layer with its own unique fingerprint. It can be called “semi-conventional.”

In the drilling process, Thyne was told, there are zones in the Yeso that show good oil saturation and porosity, “but the oil doesn’t move because the permeability is really low.” When the geologist asked for an opinion, Thyne replied that “it’s consistent with a wettability issue. That’s what makes oil move easily or not easily. It’s wettability.”

Building on ESal’s Foundation

Jan Donath

ESal’s story began with their experimentation in the wettability of water used in waterfloods in conventional wells. But, as seen here, for unconventionals, for which waterfloods are not an option, the salinity and wettability are applied in the completion process instead.

They developed a proprietary, modified flotation test in the laboratory to measure the wettability of oil-containing rock as the water’s salinity is altered.

Optimally, the producer takes that information and blends produced water with fresh water to attain the right salinity. Regardless of any other chemicals, Thyne says matching the formation’s wettability is by far the most important factor.

Using produced water has the extra benefit, he pointed out, of reducing saltwater disposal. “Now we [minimize] the earthquakes, and you make money selling it: you make money taking it for disposal, and then you make more money selling it as an EOR agent to somebody with a water flood or with a completion that they want to do.”

BASF: Working on our Chemistry

As stated, conventional and unconventional EOR methods have vastly different DNA. For Jan Donath, vice president, The Oilfield Chemicals team of BASF, working on chemistry is a team effort with producers.

George Herman

“The Oilfield Chemicals team of BASF works directly with operators to develop chemical technologies, like surfactants for both conventional and unconventional EOR, that meet the specific needs of the individual operator and are often tailored down to the level of a specific asset. We serve as the dedicated interface between the oil and gas industry and the deep scientific and technological resources of BASF.”

Donath added that the company’s wide chemical selection and expertise means they can work with service companies or operators in a wide variety of applications.

Optimizing chemical treatments requires knowledge of the formations, said BASF’s Global EOR Technology Leader George Herman. “Highly carbonate reservoirs with interconnectivity benefit greatly from both wettability alteration and reduction in interfacial tension (IFT) during the surfactant drive, pushing oil to the production well.” On the other hand, tight shales rely on a huff-n-puff process of injection, soak, and production from a single well and have less emphasis on the IFT component.

In either type of formation, knowledge of reservoir conditions and the producer’s injection fluids is an important foundation, Donath continued. “We start with listening, asking questions, and building a shared language with our customers. Once we have that, we integrate our academia-level EOR lab capabilities to run tests measuring everything from wettability to interfacial tension, to formulate the most compatible surfactant solution. From there, customers typically run a field trial.” The field results verify if the formula worked or if it needs further tweaks.

Changes in Attitudes

EOR options are gaining more traction for several reasons, Donath said. The maturing of the Permian with Tier One prospects being drilled up is one thing causing producers to revisit older wells that were fractured with older, less effective methods. Second, it also is due “in part to enhanced confidence in EOR technologies, but it is also true that evolving market conditions and shareholder expectations have played a role.”

He added that recent oil price drops due to international competition and tariff concerns are among the conditions pushing capital discipline. “With tighter capital and rising pressure for near-term returns, producers are turning to high-performing, cost-effective solutions, and that is where BASF Oilfield Chemicals acts as a focused and committed partner to the oilfield.”

Herman sees a turn toward simplicity in the industry as well. “We are seeing a trend away from older, more complicated surfactant formulations, as these can make a project business case very challenging. At BASF we focus on high-performing surfactant chemistries that are reliably producible, because we know that the best surfactant in the world is just a nice experiment if there is no way to make it economically at scale.”

Paul Wiseman

Paul Wiseman is a long-time writer in the oil and gas field.

The post EOR Enters a New Era appeared first on Permian Basin Oil and Gas Magazine.

pboilandgasmagazine.com (Article Sourced Website)

#EOR #Enters #Era