Click here to listen to the Audio verison of this story!

A pair of TCI burners, still resting on a trailer, await deployment at a drill site.

Permian Basin methane emissions have dropped by 20 percent since 2022, even as production has increased, according to a S&P Global study, as reported on this magazine’s website (tinyurl.com/yc6jd2pt). That good news is a result of many different approaches, and three of them will be examined here. Total Combustion, Inc., Reliable Oilfield Services, and MaCH4 (CH4 relating to methane, of course) here share their approaches to reducing greenhouse gas emissions.

Flameless Burners

Driving through Permian Basin roads at night, one will notice, with just a casual gaze at the landscape, scattered bright orange fires suspended in space. While those flares are among the ways to safely dispose of waste natural gas, Total Combustion Inc. (TCI) has an alternative. Their burners consume 99.9 percent of combustibles from wellheads and other emitters, without the bright glow.

While TCI’s burners don’t provide a night light for reading or navigation, they’re much appreciated in town, where the constant light would be a nuisance. They are also somewhat quieter than flare stacks, said Joe Pfaff, sales manager for TCI USA.

Being neighborly with burners instead of flares is becoming more important as, even in the Permian, production activities are moving closer to town. Pfaff says he’s seen that in person. “When I was there [in Midland] in the spring, they [producers] were really encroaching on the city itself with their operations.”

Like flare stacks, one of the top uses for TCI’s burners is for new production, when the oil flows into tanks but there’s no connection for the associated gas. Pfaff explained, “Lots of times we’ll go out there and we’ll have a one-week or a two-week flow back, that initial flow back, where we dump that gas out of the well and get that oil flowing a little bit better.”

Besides those cases, “The other work that we do in that area is pipeline blowdowns or any gas infrastructure work, where they would typically [otherwise] vent that gas to the atmosphere.”

its are available for sale or for rent, and those temporary situations make rentals a great option.

Regulatory Push?

Joe Pfaff

When asked if the Biden administration’s push toward reducing emissions had motivated more producers to use TCI burners, the answer was nuanced. One part was the no-flaring, good-neighbor issue, said Pfaff. “I think all of the oil companies want to be the best neighbor that they can be within a budget.”

But also, emissions regulations are “forcing their hand a little bit,” to start with, but Pfaff sees that leading to real buy-in after the client sees the benefits. “Once they see it and they start to accept that that’s the best way to do it for the environment and for everybody around them, they seem to get on board a little bit quicker and easier.”

That’s especially true for bigger producers, said TCI’s Business Development Manager Jamie McDowell. “That’s an image issue for them. They have departments that are dedicated to trying to be more environmentally friendly.” He added that smaller producers are often more economically challenged on this score than the majors, with less budget for things that don’t directly bring a profit.

McDowell also noted that regulations can vary widely by state, which can affect burner/flaring adoption levels.

Emissions compliance activity is spreading to tanks which, Pfaff said, have before been a forgotten emitter. In today’s world, “You’re seeing a lot more combustors trying to tackle that methane emission coming off tanks.” Now, he continued, “They’re piping that into a small combustor and burning that gas off.”

Location, Location

Pfaff noted that TCI, based in Red Deer County, Alberta, has their U.S. office in Greeley, Colo. While they have done some business in the Permian, both in Texas and New Mexico, they’re looking forward to having a greater presence here.

AI Enlightens Flares’ Data Darkness

Jamie McDowell

Keeping up with flares and equipment that’s scattered across counties and state lines can be not only time consuming, but can, if not done vigilantly, lead to noncompliance or even danger. That’s why Brian Phetteplace was instrumental in creating an AI-based flare monitoring system. And it’s why he founded a company, Reliable Oilfield Services, to offer it to the industry.

Through years of working in the field on flares, dehydrators, and “pretty much anything that’s supposed to be on fire in the oil field,” he’d noticed some blind spots. “And I hoped to bring a little bit of light to them.”

He knew constant monitoring, with data management from AI, would go a long way toward lighting that darkness. To that end he enlisted John Kramer, whose Houston-based company is called Electrosoft, to lend his expertise to creating a system that would work.

“He’s been working on controllers for decades now,” Phetteplace explained, adding, “We got together and I gave him my ideas and my thoughts and how I thought something should work. He’s been a key, key person there.”

After two years of work, they were ready to bring Reliable Oilfield Services to life.

The first step out of the monitoring darkness is to give the AI some data to monitor. This is done by installing sensors on the equipment, along with remotely operated valves, which the system can control in an emergency. As with most AI systems, it’s looking for trends and outliers. Trends, as in a thermocouple or valve whose temperature is slowly moving toward the maximum safe level. It also tracks the amount of time a typical valve lasts before being replaced. Outliers include any kind of sudden change.

With the training done by Phetteplace and Kramer, the AI’s predictive abilities get into gear. Phetteplace explained, “It sends out predictive messages. If we’ve got thermocouples that are consistently seeming to fail or getting overheated and the controller’s shutting everything down, it’ll give you a range of time in days, months, weeks on how long the thermocouple will last or when it should be replaced, along with solenoids and other pieces and components that are connected to the equipment that’s out in the field.”

Because it is Wi-Fi enabled, it sends alerts to phones or computers, and it receives instructions or overrides from authorized personnel. In those alarms, “It’ll tell you exactly what’s wrong, where it went wrong, and either what you need to do to fix it or who you need to get out there to fix it,” Phetteplace said.

The first goal is, as he explained, to be proactive and prevent issues from happening at all. But when an emergency does come, he said the system can shut down the supply valves to the burner, to keep it from emitting raw gas into the air. This also greatly reduces the need for constant site visits, meaning that a technician usually only has to go to the site for preventive maintenance on an appropriate schedule, or to solve a specific issue.

Regulatory mandates require 98 percent efficiency, and Phetteplace says they achieve that with monitoring and with backup systems that can step in when needed.

Reliable Oilfield Services can install both burners and sensors, or just the sensors if a client already has the flares in place. And, if needed, they can monitor the system for the client, although Phetteplace says most operators prefer to do that in-house.

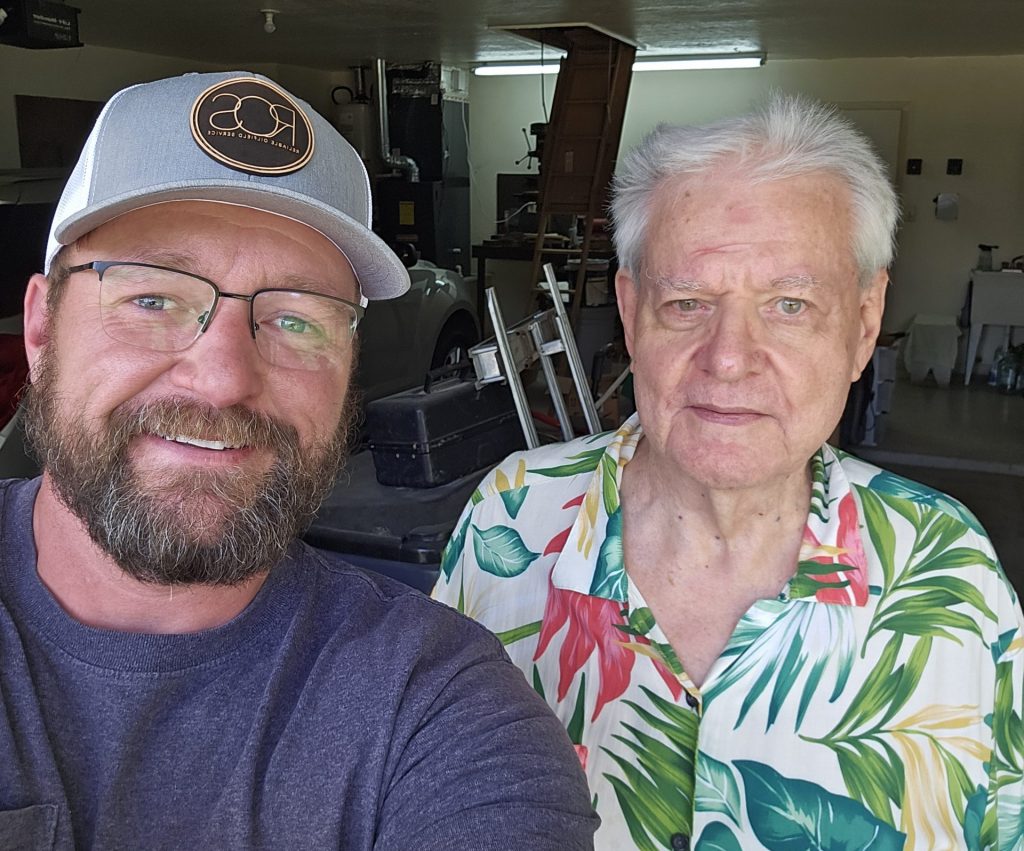

Brian Phetteplace (left) and Jon Krahmer.

In the Field

After overcoming the oilfield’s classic punch line, “We’ve never done it that way before,” Phetteplace says the response has been even better than he’d expected. And feedback led him to an update, adding an onsite screen—something he’d originally resisted because they can be a challenge to maintain onsite.

Since then, “All in all, I’ve heard nothing but praises,” he said. Clients include producers of all sizes and shapes. Basically, “We work with everybody,” as far as company type.

Coldstream Energy’s MaCH4 Reduces VOCs

Methane is indeed a big issue, but volatile organic compounds (VOCs) emitted by site-gas-fueled compressor stations are another. Processing the feedgas to remove natural gas liquids (NGLs) and other heavy hydrocarbons before being fed into the engine is important in reducing those VOCs.

To that end Coldstream Energy in February of 2025 announced the release of its patented MaCH4 NGL recovery system, with Archrock as their Strategic Distribution Partner for MaCH4.

Coldstream’s Senior Vice President of Sales and Marketing Matt Thompson explained how MaCH4 is different. “We’re using a technology called Pressure Swing Adsorption [PSA] to separate heavy hydrocarbons from methane at compressor stations. As a result, we are providing incredibly lean/clean fuel gas for the compressor engines while injecting the NGLs MaCH4 has separated back into the pipeline system [in gaseous form to be monetized downstream at a processing facility.”

Existing standard procedure for compressors is to run either on field gas or for the company to deploy a J-T skid or membrane to treat the fuel gas, Thompson said. A J-T skid uses the Joule-Thomson effect to recover NGLs by chilling high-pressure gas with a pressure drop through a Joule-Thomson valve. That causes liquids like propane, butane, and others to condense into a liquid, leaving the gas available to the motor.

Matt Thompson

The problem with J-T skids, said Thompson, is that they are far from 100 percent effective in cleaning the gas, leaving a lot of the heavier NGLs in place—and by liquefying the NGLs, they must then be trucked out for sale, which can devalue them by as much as 50 percent. That loss of monetization is a kind of hidden cost in that system. Also, leaving the heavier gas in the burn mix increases CO2 emissions.

Membranes, the other common option, tend to be unreliable because they only work well with high pressure flows “meaning it takes a lot of gas volume to produce the necessary fuel volumes.”

On the other hand, MaCH4’s PSA system “has zero liquid dropout,” leaving the NGLs in the line in gaseous form to be monetized at full value downstream, Thompson said.

MaCH4’s high level of NGL removal is where the reduction in VOCs comes in, said Thompson. VOCs always come from the engine exhaust. So “Because we provide the leanest fuel, we have the lowest VOC emissions” compared to J-T skids, or to completely untreated gas. Coldstream studies have shown a 70 percent reduction in VOCs and an 8 percent reduction in CO2 with MaCH4.

Thompson expounded the full benefits of the system as follows: “There are really four value drivers for MaCH4: NGL recovery, VOC emissions reduction, reduction of downtime from poor fuel [engine detonation], and horsepower increase.”

So, while there’s a somewhat greater initial cost for MaCH4 compared especially to J-T skids, it’s overall a net gain, Thompson said. “Technologies that deal with emissions tend to be a sunk cost, as opposed to a technology that is an asset with positive NPV [net present value, or projected future cash flows]. That’s why we lean into NGLs simply because we want MaCH4 to be viewed as an asset that produces revenue as opposed to a cost.”

A Reliable Energy Services installation.

Where and When, Eyes on the Permian

The company’s pilot unit has been operating in central Oklahoma since late 2023. Their first commercial unit is humming along for a major midstream firm in western Oklahoma, and, at this writing, that company was planning to add a second unit in Q4 of 2025.

And Thompson is excited about a Permian future, saying, “We are currently working on a project with a Permian customer to deploy our first unit in that basin. There is a lot of interest in the Permian.”

Their Archrock connection provides an open door to growth in this region, he said. “With our partnership with Archrock, and their strong Permian position, we see MaCH4 being very successful for the Permian Basin.”

Paul Wiseman is a longtime writer in the energy industry.

The post Cleaner is Better appeared first on Permian Basin Oil and Gas Magazine.

pboilandgasmagazine.com (Article Sourced Website)

#Cleaner