A SHALE exclusive by Zalak Purohit

As the global energy industry pivots toward greener sources, natural gas has gained prominence as a reliable transition fuel. More than $37 billion is invested worldwide in enhancing gas distribution and transmission infrastructure. With rising demand, the production, processing, storage, transport, and distribution of natural gas must scale accordingly. In this environment, intelligent measurement solutions have become indispensable to balancing cost efficiency, environmental sustainability, and regulatory compliance,.

The precise measurement of hydrocarbon volume and quality is central to optimizing processes and achieving cleaner, more efficient operations. Instrumentation forms the backbone of these intelligent systems. With a variety of technologies available, selecting the right solution for fast-evolving measurement needs is both critical and challenging. The U.S. Environmental Protection Agency (EPA) has established detailed norms and performance standards for flare gas measurement, particularly aimed at controlling emissions in industries like oil and gas (O&G), petrochemicals, and refining. Regulatory compliance requires operators to maintain records of all performance tests and submit emissions data, typically on a quarterly or annual basis, depending on the type and size of the facility..

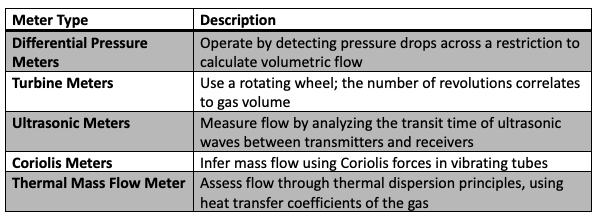

As an engineer working on O&G projects in North America for 15 years, I have observed various technologies employed in natural gas measurement. The most common are summarized as follows:

While differential pressure, turbine, Coriolis, and thermal mass flow meters each have their own advantages, they come with limitations that can affect long-term performance in certain applications. Turbine meters, for instance, have moving parts that require regular maintenance and can degrade in accuracy over time. Coriolis meters offer high precision but are often more expensive and bulky, which can make them less suitable for retrofits or space-constrained environments. Thermal mass flow meters perform well with clean, dry gases, but can struggle with fluctuating gas compositions or harsh field conditions.

In my experience, ultrasonic technology, which entered the gas flow measurement industry at the turn of the millennium, has proved to be the most well-suited for today’s complex and dynamic gas measurement needs. Ultrasonic meters are smart, connected sensors that come with an intuitive software interface that allows for easy commissioning and meter start-up, and facilitates efficient monitoring of system status, meter live values, and trend charts. New technology meters have the additional capability of remotely monitoring the health of the instrument and sending real-time data to plant operators for predictive maintenance and system alerts. With increasing demand in smart sensors and connectivity between various sensors within the plant, this technology is gaining popularity despite its relatively higher cost. .

The rise in acceptance for ultrasonic flow measuring systems has enabled me to utilize this technology in different use case applications across systems engineering, process flow design, and technical project management. In these capacities, I have found that ultrasonic meters presented the best solution in three specific processes.

- Upstream extraction EPA reporting

In upstream operations for natural gas extraction, a customer required a solution for the continuous monitoring and mandatory reporting of gases flared into the atmosphere, with targeted uncertainty of +/- 5%. By its nature, the pressure, volume flow, and gas composition in a flare stack can vary significantly over short periods of time. Traditional-type flow meters could not handle the fluctuating gas composition, and had high pressure drop. We recommended ultrasonic technology, with complete system assembly and calibration, to meet the measurement requirement of low flow to high flow varying from 1 ft/s to 300 ft/s. Due to the non-invasive nature of ultrasonic sensors, there was virtually no pressure drop, and the technological superiority of ultrasound technology enabled it to handle fluctuating gas composition in the stream, thus meeting the operator’s requirements. Additionally, the real-time sensor data feed helped the customer create dashboards to expedite reporting the gas emissions and compliance with project norms.

- Gas measurement for custody transfer

After production and processing, a customer needed a flow measurement solution to measure natural gas sold to transporters who bring the gas to market. When gas ownership changes hand, having precise and accurate measurement is crucial, as even minor errors in handling such large volumes can lead to major financial losses. Traditional flow measurement meters incur high pressure drop, and their moving mechanical parts require frequent maintenance. To overcome the challenging accuracy requirements with low pressure drop and a maintenance-free solution, ultrasonic measurement technology was offered to the customer. Our comprehensive solution included meter runs installed upstream and downstream of the meter to meet the customer’s piping specifications, and the complete assembly was flow- calibrated to meet a demanding deviation requirement of <0.1%. Although the adoption of ultrasonic technology exceeded the initial budget, the customer recognized its long-term efficiency and approved the proposal. In this case and in numerous custody transfer applications, the benefits of ultrasonic technology made the cost worthwhile.

- Retrofitting differential pressure meters

While differential pressure meters are extremely popular among operators performing offshore operations, these meters lack installation versatility and real-time reporting capabilities. In one situation, the existing differential pressure transmitters were not equipped to handle the reporting requirement, and were causing an undesirable high pressure drop in the system. The customer required a retrofitting of the offshore platform with newer sensors to capture gas flow data, without any collateral impact on the pressure. Given the space and weight limitations inherent to offshore platforms, retrofitting meters into the existing footprint while meeting the smart sensor data recording needs, was a challenging project. Because ultrasonic meters are scalable and agnostic to the flow pipe dimensions, we conducted an assessment to check the feasibility of introducing ultrasonic meters in to the existing set-up. Because ultrasonic sensors has a fixed connection profile, we were able to accommodate the sensors within the existing set-up by re-designing the flow pipe. The sponsor approved the project, which was implemented in record time and within budget.

In each of these use cases, the superior sensor-based connectivity of ultrasonic sensors, their capability to measure flow without causing pressure loss, and their ease of installation within existing engineering systems offered benefits that were unmatched by traditional measurement technologies. Ultrasonic meters also provide other advantages related to the efficient and safe management of gas flow operations in-line with regulatory norms. For example, ultrasonic meters do not have any moving parts, enabling a longer operational life, while reducing maintenance downtime and expenses. Additionally, ultrasonic sensors share data in digital format, which can be collated and aggregated by reporting platforms to provide plant managers with a holistic view of flow data across the unit. Furthermore, in the oil and gas industry, operations with cyclical energy demands can leverage this technology to accurately measure bi-directional gas flow between storage facilities and end users, eliminating the need for separate meters and complex piping — resulting in significant cost savings.

Thus, while ultrasonic meters are costlier than the traditional meters available in the market, the gains achieved in terms of accuracy and lower operational cost make them a preferred choice for future-proofing gas flow measurement needs. As the energy sector continues to evolve, ultrasonic flow measurement stands out as a smart, scalable, and forward-looking solution that meets the demands of both current operations and future regulatory and efficiency goals.

About the Author:

Zalak Purohit is a senior systems project engineer at Endress+Hauser based in Houston, Texas. Specializing in technical project management and the application, design, and build of ultrasonic flow measuring systems for the energy industry, Zalak is highly experienced in process flow design and EPC projects, managing complete engineering lifecycles from design, procurement, fabrication and assembly through testing. She additionally provides expertise in rotating equipment, data communications, and hazardous area classification equipment and instrumentation requirements to oil and gas industry operators in the U.S. and Canada. Zalak earned a B.S. in Mechanical Engineering from Osmania University (India), and received her M.S. in Mechanical Engineering from Texas A&M University (US). She is a Licensed Professional Engineer in Texas, certified by the Texas Board of Professional Engineers and Land Surveyors (TBPELS), and has advanced professional education from the American Society of Gas Measurement Systems.

Keep In Touch with Shale Magazine

As the new era of energy unfolds, you can bet we’ll be the boots on the ground to keep you informed. Subscribe to Shale Magazine for sharp insight into the arenas that matter most to your life. And don’t forget to listen to our riveting podcast, The Energy Mixx Radion Show, where our very own Kym Bolado interviews the most extraordinary thought leaders, business innovators, and industry experts of our time.

shalemag.com (Article Sourced Website)

#FutureProofing #Gas #Flow #Measurement #Ultrasonic #Technology #Shale #Magazine